I had wanted to add a couple of gauges to the ACR. The first was a fuel pressure gauge attached to the regulator so I can get a visual reading of the fuel pressure while it is idling and/or on the dyno at WOT. The other gauge I wanted to add was an in the cabin oil pressure gauge. I bought an AEM pressure gauge so it would match the existing AFR and Boost gauges already in the vehicle. I also bought a new gauge pillar that will hold 3 gauges.

I decided to feed the wires through the grommet that is tucked up and away on the drivers side. The thing is absolutely stuffed with wires already! But I managed to get the huge pressure sensor plug through Ė it took a long time and was quite annoying. Unfortunately the annoyance didnít stop there, as I had to do quite a bit of messing with wires, cutting tie wraps and pulling wires back and forth just to remove the existing gauges from their pods and then get all the gauges back in to the new pillar. Anyhow, itís all worked out now, and the gauges are in place. Iíve got to get some double-sided tape to stick the new pillar over top of the OEM one to keep it in position. Then Iíll have to neat up all the wires and finish hooking up the oil pressure sensor wires for power, etc. Funny how this kind of shit eats up so much time.

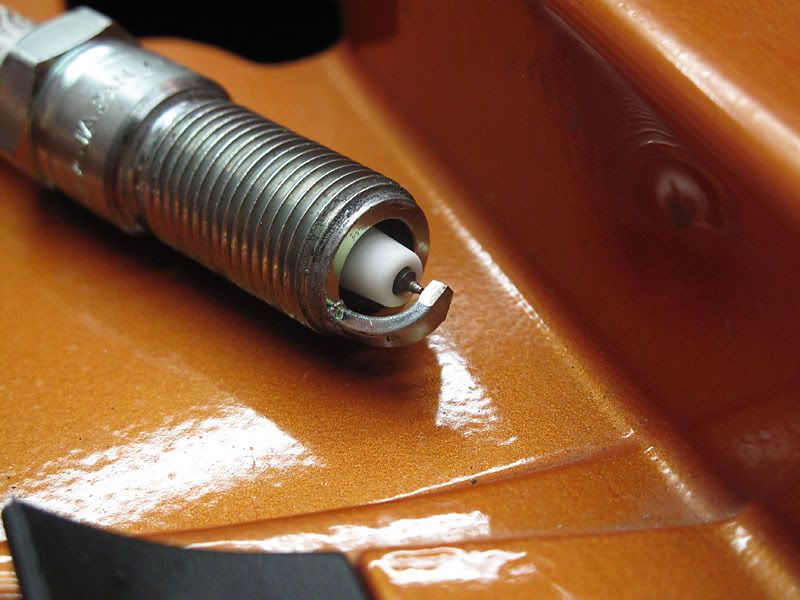

On the mechanical end of things, I removed the fuel rail briefly because the upper coolant pipe clamp would not go on with the fuel rail attached. Additionally, I did not put in the oil dipstick previously, and found that difficult to do with the fuel rail fastened. I also hadnít routed the hosing for the PCV valve nor did I put the PCV valve in to the valve cover. Decided that I should maybe consider putting the main crank pulley on. Alas, the mysterious bolt bucket has failed me. Iíve got no main crank bolt. Fortunately Iíve got a spare SRT-4 engine sitting in my garage. So I stole the crank pulley bolt from that engine. Then I fastened the main crank pulley. I slipped the alternator belt over the pulley (Alternator is not yet installed) and then I put on the accessory drive belt. At this point, I noticed the auto-tensioner was never properly fastened, so I fixed that up and put the accessory drive belt on.

I retrieved the hood from my garage rafters, bolted that on and hooked up the windshield washer fluid supply line.

Hooked up the shifter cables and fastened the mounting bracket. Went inside the car and verified that the car goes in to all the gears. Took note that the throw on the shifter seems ridiculously short. I have no idea what gear shifter Iím going to find in there when I remove it. But unless for some reason I really really really like this thing after I have this heap running, I will probably remove it in favor of a Mopar STS. That is what I am used to in my other SRT-4, and I really like it a lot. Weíll see what happens.

I installed the oil pressure sender unit in to the head. I used aviation liquid sealant w/teflon on the threads. Tightened that up, and routed the wire connector to it and installed it. Also hooked up the camshaft position sensor, speed sensor, and the other sensor at the rear of the block.

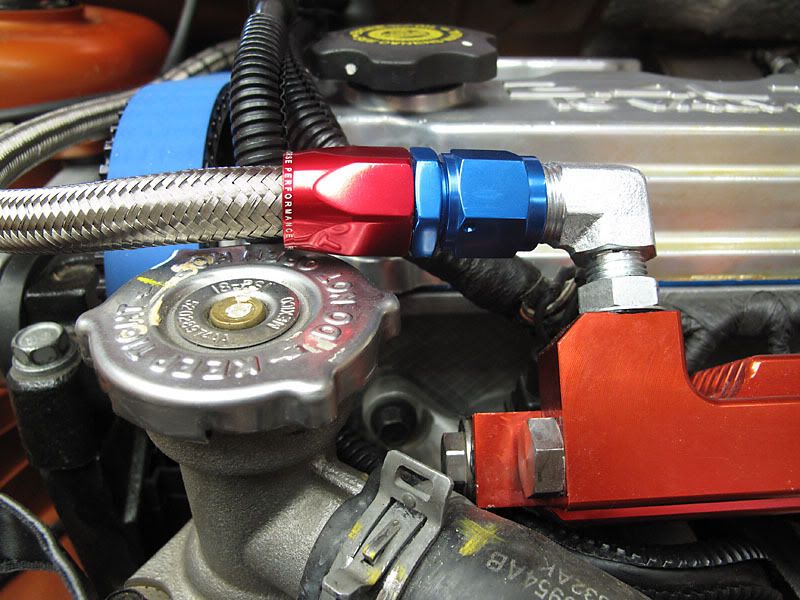

Next I went under the car to route the fuel feed line. I bought the fittings and hose and just made the line myself. [Letís pray it doesnít leak, right!] So, plenty of black zip ties later, the fuel feed line has been secured.

Quote

Quote