Just bought this in late March of 2012.

Orange Blast w/Pearl Coat

1 of 210 Orange ACR's ever produced

Has just 13,477km on the odometer

Should be interesting...pics to follow, eventually.

Edit: I've been meaning to compile a list of the vehicles modifications. I'm not sure it is totally complete here, but this is a pretty good list of what is in the vehicle:

Modifications:

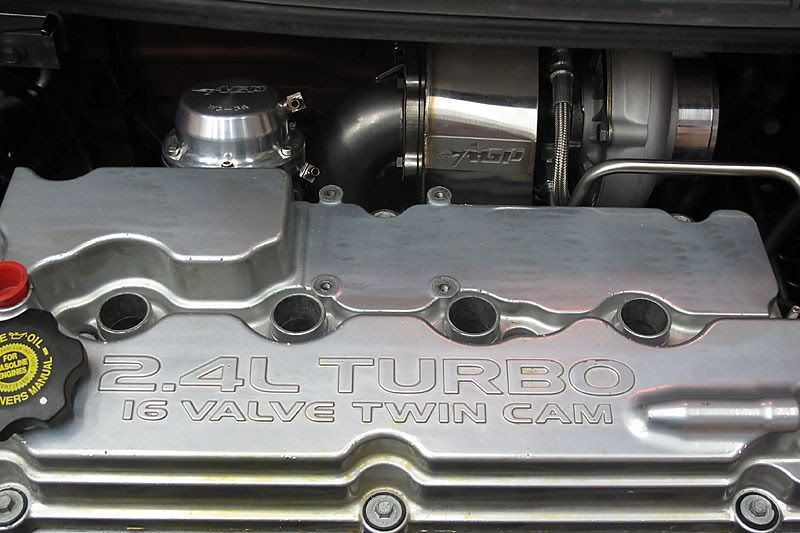

Engine:

DCR Stroker 2.6L

Darrell Cox Racing - 2.6L DCR Stroker Short Block High Output (Powered by CubeCart)

DCR Pro Series Head

Darrell Cox Racing - Pro Series Cylinder Head (Powered by CubeCart)

Gates Racing Timing Belt

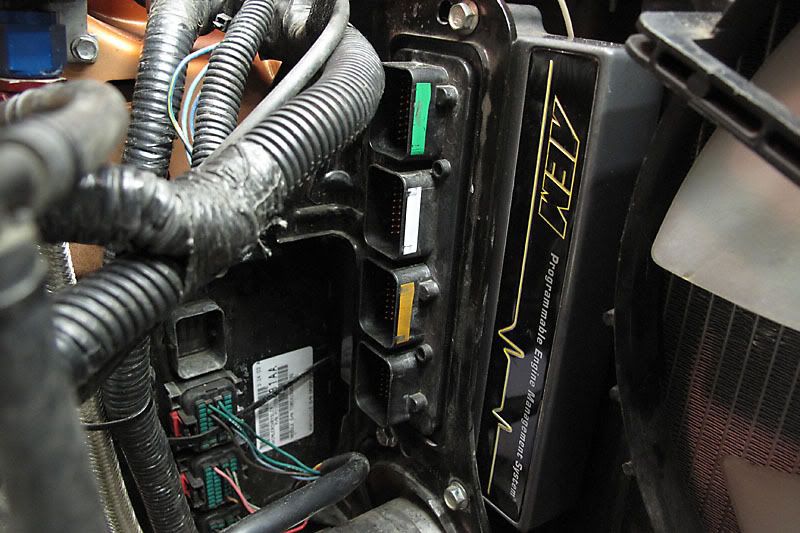

Electronics / Engine Management:

AEM EMS Non-UEGO w/OEM PCM

AEM UEGO Wideband A/F Gauge

AEM Tru Boost Electronic Controller w/Gauge

AEM Pressure Gauge (Oil)

Aeroforce Scan Gauge in OEM boost gauge location

Turbo Package / Exhaust:

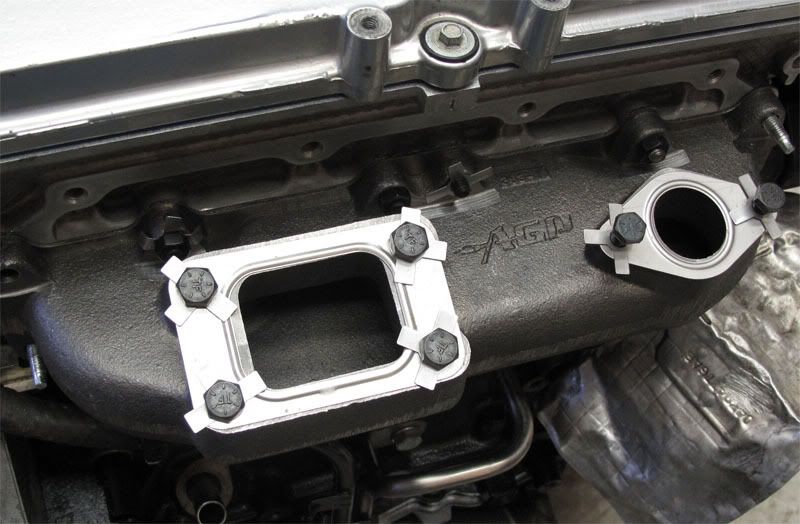

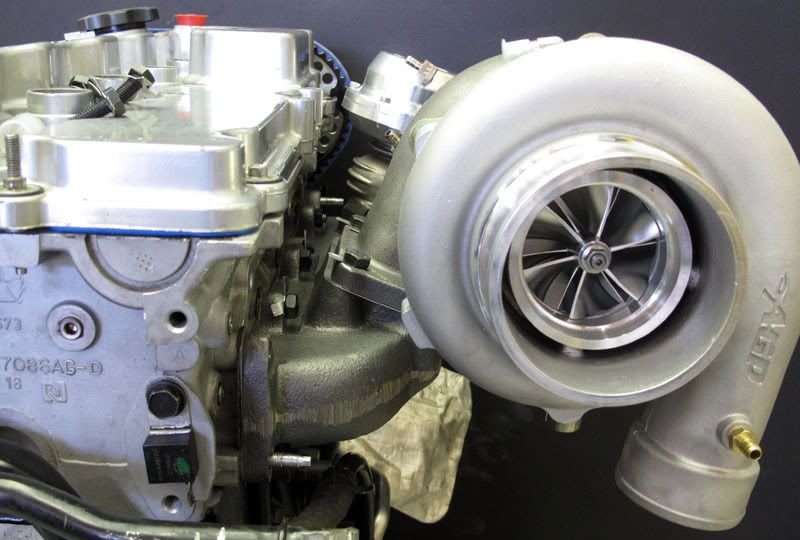

AGP Zeta 3.2 BB Turbocharger 82 A/R

AGP Exhaust Manifold

AGP 3Ē O2 Housing

AGP Dump Tube

AGP 38mm External Wastegate

MPx 3Ē Downpipe & Full Catless Dual Exit Exhaust

Transmission:

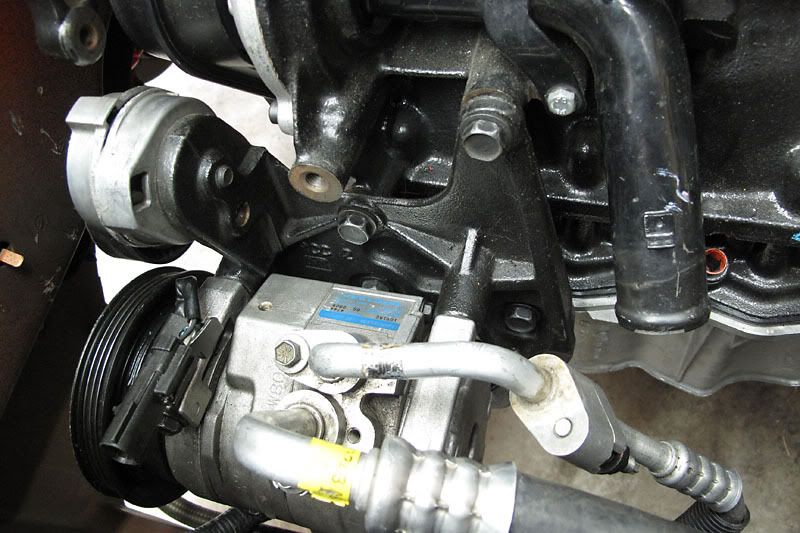

PWerks Stage 3 Tranny

RageTek Hydraulic Release Bearing

Clutch/Flywheel (Unknown, as I did not take it apart lol)

[I know I will be soon enough!]

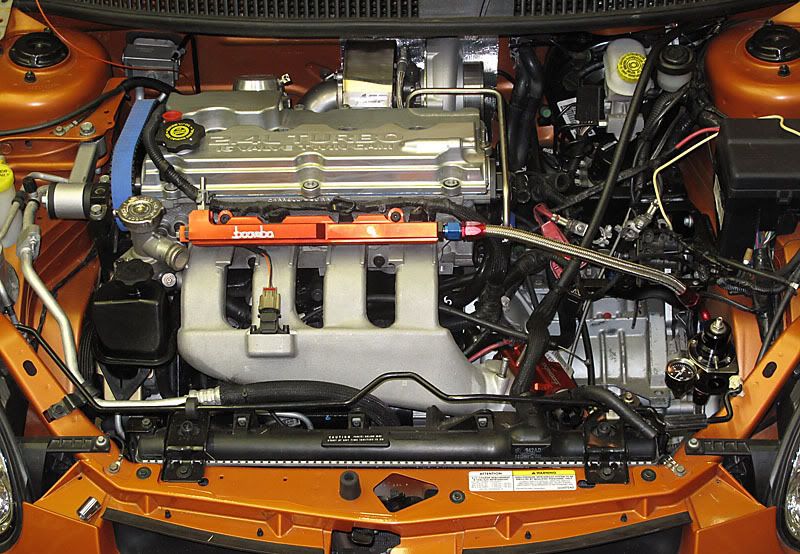

Fuel:

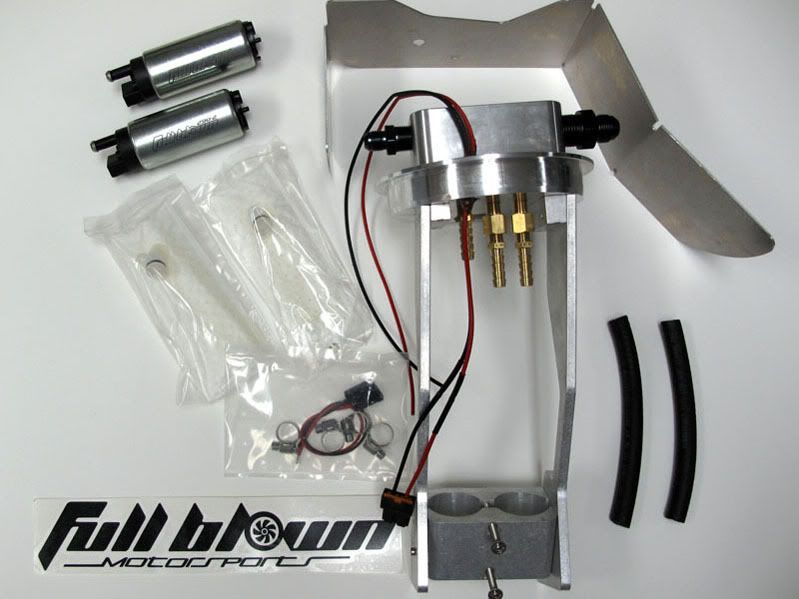

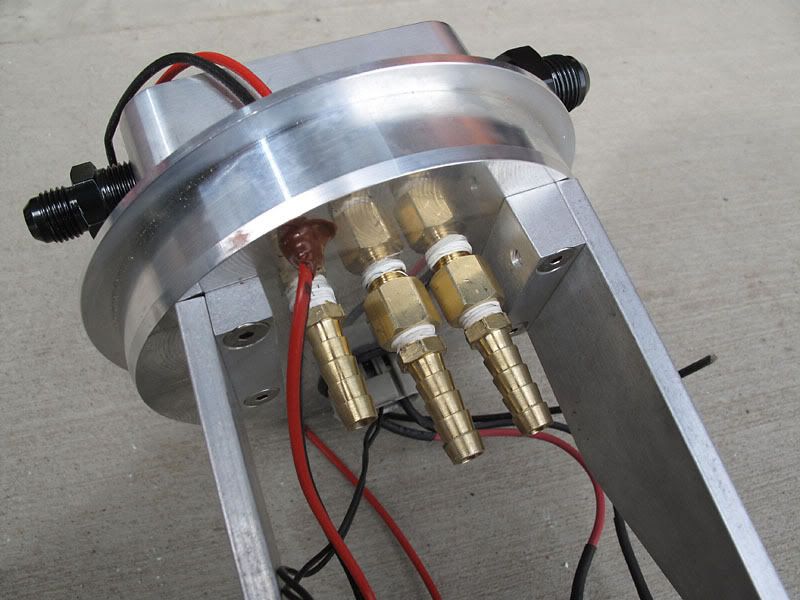

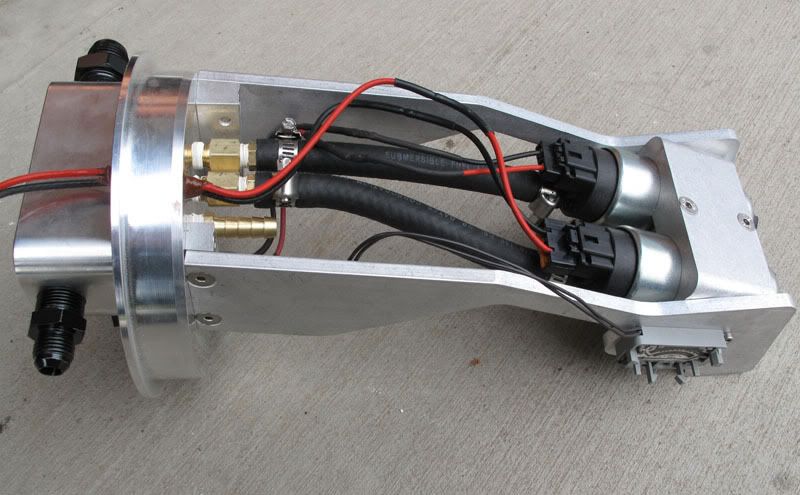

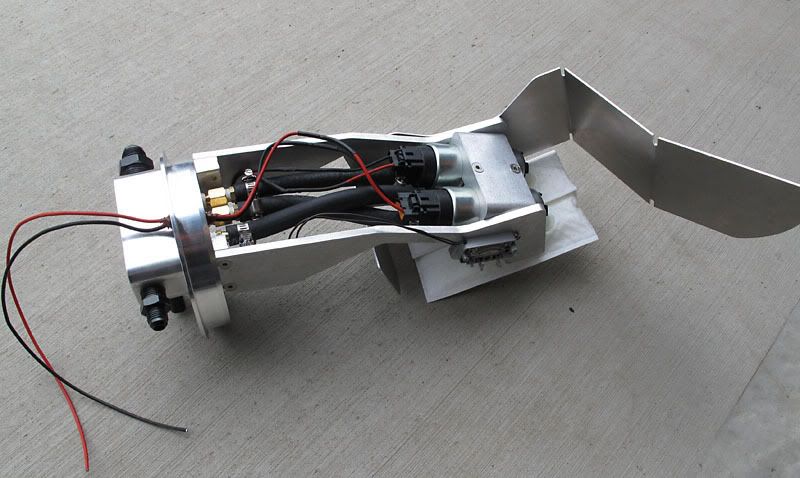

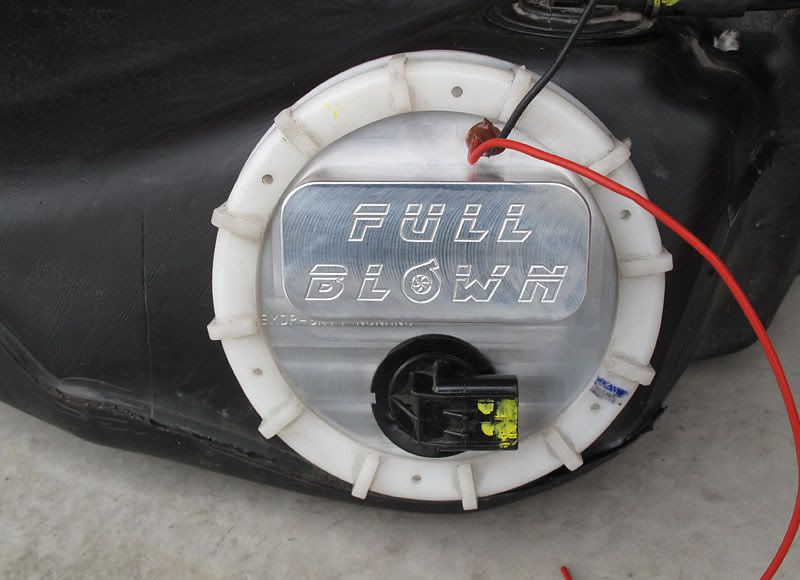

Full Blown Dual Fuel Pumps

AGP after rail FPR & return line

AN-8 Feed, AN-8 Return

Boomba Fuel Rail

In rail fuel pressure gauge

RC Engineering 750cc Injectors

[1200cc/1400cc Injectors to go in at Dyno]

Air / Intake / Intercooling:

JMB Ultimate 3Ē CAI

Extrude Hone Intake Manifold

Boomba 70mm Throttle Body

Custom Tubes Intercooler, Anodized Black

Cold Side Hard Pipe

Turbonetics Blow Off Valve

Suspension / Axles:

Mopar Performance Stage 3 Coilover Suspension Kit

DSS Level 3 Axles

Quote

Quote